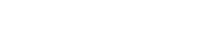

Why our Tubular Heater is your Best Choice?

Discover the outstanding features of WITSTO tubular heater.

Multiple Sheath Choice

Numerous sheath materials are available for various working environments. #304 & #321 stainless steel are recommended to operate in 300-500℃ while S310 for higher temperature applications.

Pure MgO Powder

MgO powders applied to our tubular heater reach a purity of 97%. They are filled & compressed to an optimum density for best insulation & efficient heat transfer from the resistance coil to heating medium.

Custom Bends

Our tubular heaters can be configured to an unlimited number of shapes & sizes depending on your equipment size, the desired watt density & other operating requirements.

Bespoke Terminals

We provide custom terminals which allow for easy installation. Terminals that connect perfectly with your equipment also help to improve the heating efficiency & lifetime of your element.

RTV Silicone Seal

RTV silicone seal, which boasts excellent insulation & anti-corrosion properties, helps to prevent moisture & other impurities from affecting the performance of the inner resistance coils.

Additional Fins

Fins can be fitted to your tubular heater to increase the convective surface for air or gas heating. Fin spacing & sizes are optimized to improve conductive efficiency while producing lower sheath temperature.