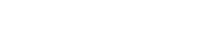

Craft for demanding applications

Discover what makes our heater perfect for immersion environment.

Anti-Oxidized Sheath

For demanding applications in water, oil or other liquids, we offer premium Japanese SUS 304, 316 or Incoloy 800 alloy for sheath building, which has good resistance to oxidation at elevated temperature.

Scale-Resistant Coating

The scale can greatly affect the performance & safety of immersion heaters. That’s why scale-resistant coating is applied to further protect the heater. (Anti-corrosive coating can be added if the heater is used in corrosive liquids. )

Explosion-proof Cover

For heater used to heat up explosive liquid like oil, an explosion-proof cover (with an anti-explosive grade accommodating to the application) is fitted to the head of the heater, preventing safety issues during the heating process.

Tight Seal

Seal tightness is crucial for immersion heater since leakage could pose safety risks. Argon protected welding is applied in sealing the flange & heater which prevents air oxidation while making a tight seal.